Slip resistance break down

Why Slip Resistance Matters

Slip resistance is a critical safety factor in tile selection, especially in areas exposed to water, oils, or other contaminants. Slips and falls are a leading cause of injuries in homes, workplaces, and public spaces. Choosing tiles with the correct slip resistance rating reduces risk and ensures compliance with building codes and regulations in Australia.

Relevant Australian Standards

AS 4586:2013 – Slip Resistance Classification of New Pedestrian Surface Materials

This standard outlines the testing methods and slip resistance classifications for new tiles. It specifies different test methods for dry, wet, and oil-wet conditions.

AS 4663:2013 – Slip Resistance Measurement of Existing Pedestrian Surfaces

This standard applies to surfaces already installed. It measures actual in-situ slip resistance performance rather than lab-based classification.

HB 198:2014 – An Introductory Guide to the Slip Resistance of Pedestrian Surface Materials

A handbook providing guidance on appropriate slip resistance ratings for different building applications, such as bathrooms, kitchens, stairs, shopping centres, and outdoor areas.

Slip Resistance Testing Methods

The following tests are referenced in AS 4586:2013:

Wet-Barefoot Inclining Platform Test (AS 4586 Appendix C):

Used for pool surrounds, showers, and other barefoot areas. Classified as A, B, or C (with C being the highest resistance).

Wet Pendulum Test (AS 4586 Appendix A):

Simulates a heel striking a wet surface. Produces a Slip Resistance Value (SRV) classified as P0–P5.

Dry Floor Friction Test (AS 4586 Appendix B):

Measures friction on a dry tile. Classified by the coefficient of friction (≥0.40 considered acceptable).

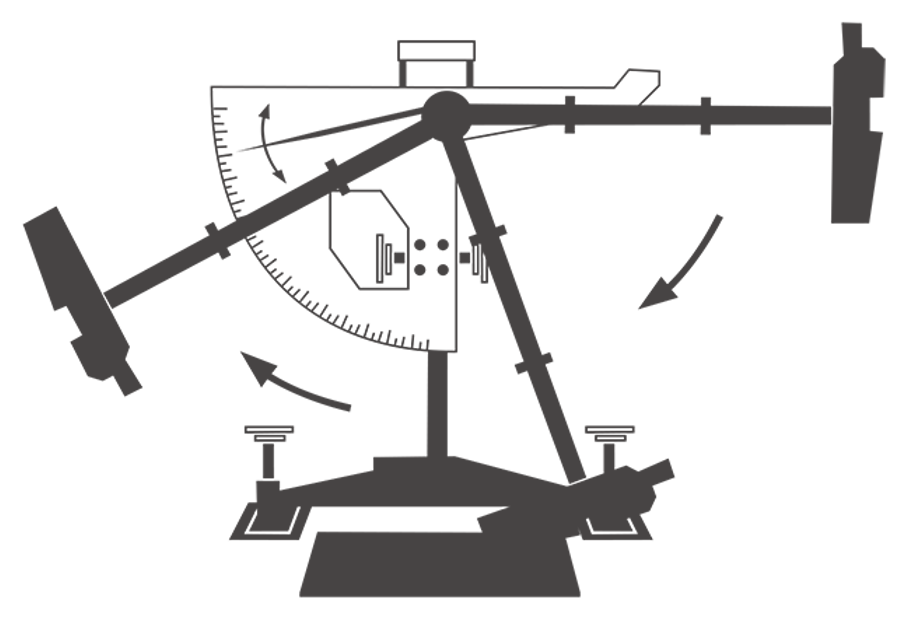

Oil-Wet Inclining Platform Test (AS 4586 Appendix D):

Tiles are tested on an inclined platform with oil, suitable for industrial or commercial kitchens. Results given as R9–R13.

Slip Resistance Classifications

The following tests are referenced in AS 4586:2013:

Pendulum Test (P-Ratings)

- P0–P1: Very low resistance, not recommended for wet areas.

- P2–P3: Suitable for dry indoor areas, residential bathrooms (low risk).

- P4–P5: High slip resistance, suitable for commercial kitchens, shopping centres, and outdoor public areas.

Oil-Wet Ramp (R-Ratings)

- R9: Low resistance (minimal slip resistance).

- R10–R11: Moderate resistance, often used in residential kitchens and general commercial spaces.

- R12–R13: High resistance, suitable for industrial kitchens, ramps, loading docks.

Wet-Barefoot Areas (A–C)

A: Low resistance, limited to dry change rooms.

B: Moderate resistance, suitable for pool surrounds.

C: High resistance, for ramps into swimming pools and wet barefoot areas.

Maintaining Slip Resistance

Even compliant tiles can become slippery if not maintained. Factors include:

Sealers & Polishes: Some coatings may reduce friction; always verify compatibility.

Cleaning Products: Use appropriate detergents that don’t leave slippery residues.

Wear & Tear: Surface finishes may degrade over time, reducing slip resistance.

DISCLAIMER All material on this website is published in good faith, however Skheme Pty Ltd does not warrant or represent the origin, validity, accuracy, completeness, timeliness, authenticity or reliability of, nor accept any responsibility for errors or omissions, in any material on this website or in any accompanying or other material, including advertisements, whether oral, visual, written, printed or electronic. Skheme Pty Ltd is not liable for any losses, claims, damages, demands, costs and expenses of whatsoever nature arising in any way, including those caused by negligence, out of or in connection with the use of this website, or any accompanying or subsequent information, or by reason of any reliance upon its contents by any person, company or organisation. All access to, and use of, the information is at the user’s risk. All technical details, recommendations and other information contained on this website represent the best of our knowledge and experience at the time of publishment. It is your responsibility to ensure that our products are used and handled correctly and in accordance with any applicable Australian Standard, our instructions and recommendations and only for the uses they are intended. Country specific recommendations, depending on local standards, codes of practice, building regulations or industry guidelines, may affect specific installation recommendations. The supply of our products & services is also subject to certain terms, warranties and exclusions, which may have already been disclosed to you in prior dealings or are otherwise available to you on request. Skheme reserves the right to alter, amend, vary or otherwise change any information on this website at any time and without prior notice to you to reflect our ongoing research and development program. The provision of any URL or link is done for the convenience of users of this website. It does not constitute an endorsement by the Skheme of that URL or link or the information at that Internet site. Potential customers should speak to a Skheme consultant regarding the qualities, colours and textures of all Skheme products before purchase.